Hundreds of reusable face masks and protective face shields that are being produced at REGENT BUSINESS SCHOOL’s iLeadLABs using 3D printed parts will be donated to healthcare professionals in the public sector.

REGENT BUSINESS SCHOOL, a member of Honoris United Universities, has heeded the SOS call from healthcare professionals fighting COVID-19 across South Africa for Personal Protection Equipment (PPE). The business school has mobilised its innovation hubs, iLeadLABs, in Durban, Johannesburg, Pretoria and Cape Town to produce its reusable protective face shields and splash protection masks using 3-D printed parts which will be distributed, at no cost, to public healthcare facilities.

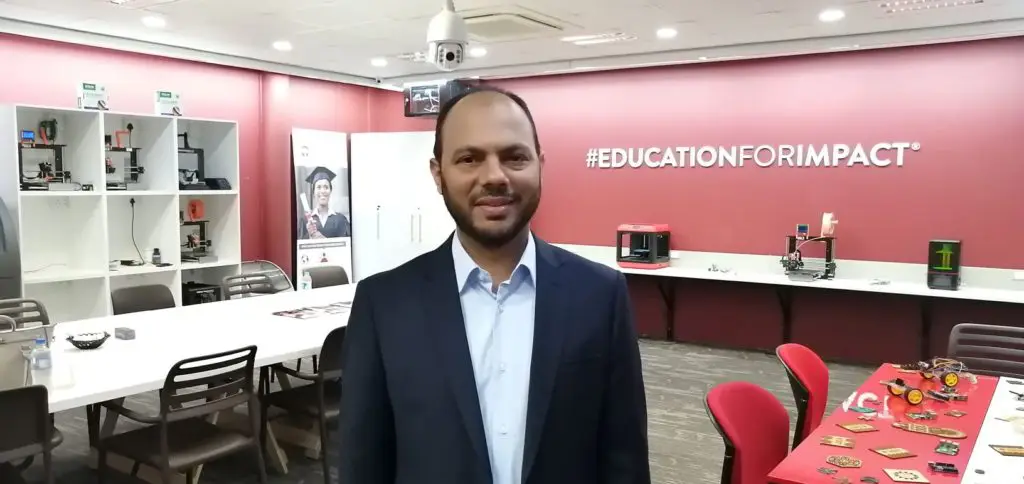

“As a socially responsible organisation, we take an agile and proactive approach against local and global concerns, so when government appealed for help to support its medical fraternity with critical protective gear, we were able to respond quickly and decisively,” explains Dr Ahmed Shaikh, Managing Director of REGENT BUSINESS SCHOOL. “The PPE shortage is a global one. We are thankful to be in a position to mobilise all of our innovation incubators or iLeadLABs across the country to do our bit to make a difference. We are fully committed to this for the long-run.”

PPE is critical to protect healthcare professionals against contracting the novel Coronavirus and plays a crucial role in helping turn the tide of the pandemic. The shields and masks will be donated to those testing and treating members of the public for COVID-19. As the demand for protective gear increases amidst rising infections, the business school has embraced the long-term challenge with a comprehensive three-phase plan.

Managing Director, Dr Ahmed Shaikh, says REGENT BUSINESS SCHOOL has a three-phase long-term plan to mobilise digital innovation to help government in its fight against COVID-19.

Phase 1 is currently being actioned. Phase 2 involves the production of fabric face masks for public healthcare personnel and patients. The innovation team has finalised this prototype and samples have already been produced. Phase 3 ramps up the design element with the production of 3D printed masks equipped with filters, the first prototype of which is already complete.

“We have a robust culture of innovation, design thinking and learning,” says Dr Shaikh, “and the COVID-19 pandemic has presented us with a unique opportunity to mobilise this mind-set to bring about significant, impactful technology-driven change within the national health sector.” He adds that apart from the three-phase social investment, the business school’s A-team is also working on other user-driven solutions designed to positively influence the health, safety and wellbeing of South Africans.

“The true grit of a nation is revealed during times of crisis, like this one,” says Dr Shaikh. “We are facing an undeniably powerful adversary – and an invisible one at that. Our business school is grateful to be able to meaningfully contribute to the fight against COVID-19 by producing and donating life-saving essential gear. It’s also our little way of showing to our invaluable healthcare workers that they are not alone, and that we are all in this fight together.”

The team comprised Dr Shaikh (Managing Director), Dr Ridwaan Asvat( Operations Director), Richard Shewry (Project Manager: iLeadLAB), Alanna Windrum (Technology Specialist: iLeadLAB), Yusuf Vawda (Engineer), Hoosen Essof (Operations Manager- Gauteng), Elmarie Verster (Pretoria Commercial Leader), Vikesh Rampadarath (Associate Director Gauteng) , Robyn Elliott (Cape Town- Commercial Leader), Liaquat Wahid (Technology specialist), Riaz Motala (RBS Campus Manager) and Keean Verster (1st year BCom Law student at Regent Business School). Each mask and protective shield takes just under two hours to produce at an iLeadLAB. The visor is plastic and the clips are made of corn starch. The first consignment was is ready for dispatch to public healthcare facilities and production is continuing 24/7, observing all COVID-19 health and safety specifications.

“We are currently in the process of contacting some of the designated COVID-19 state-owned hospitals in Durban, Johannesburg and Pretoria to ensure that the handover is aligned to the correct safety and social distancing protocols,” says Dr Shaikh. “Our visors are reusable and can be sanitised after usage which is essential in the period when PPE stocks nationally are depleting at an alarming rate.”

REGENT BUSINESS SCHOOL has currently 3D printed and assembled 200 PPE and is aiming to produce at least 500 PPE by the end of the month.

For interviews with Dr Ahmed Shaikh, Managing Director of REGENT BUSINESS SCHOOL, kindly contact Anisa at [email protected] or on 072 175 6350.